Metal Cutting Bending

Metal cutting bending, pressing, welding, screwing, assembly

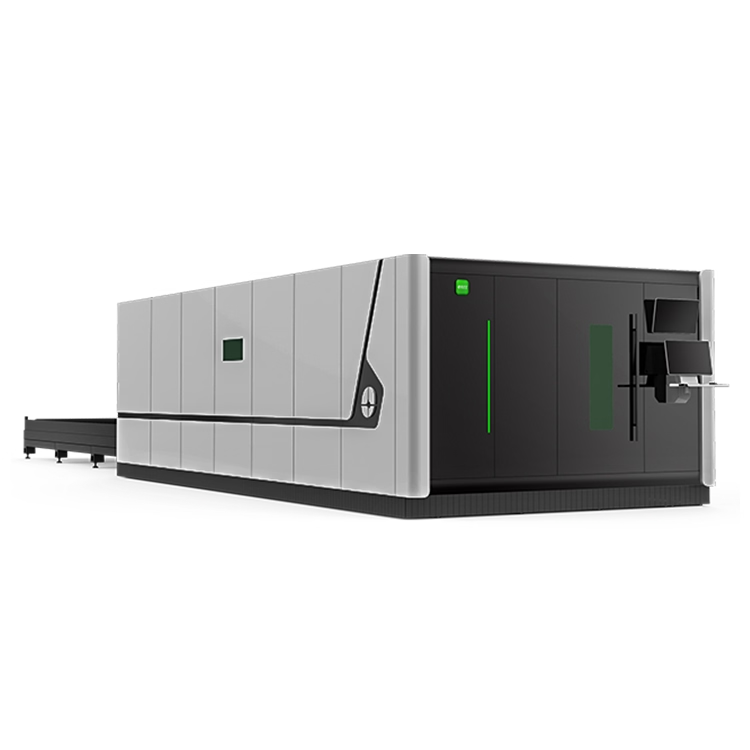

OREE OR-PH3015 3000x1500mm 6000w Fiber Laser Cutting

Thanks to its casting body, the high precision fiber laser cutting machine provides users with powerful cutting ability and efficiency, while the fully enclosed laser protective covers, chain exchange platform and professional CNC cutting system ensure safe and stable working performance.

Working area: 1,530 x 3,050 mm

Laser power: 1,000w – 6,000w

Max. speed: 140 m/min

Acceleration: 1.5 G (max.)

Laser head: Swiss Ray-tools autofocus

X,Y axis positioning accuracy: ±0.03 mm

X,Y axis repeatability accuracy: ±0.02 mm

Cutting capacities: Steel 26 mm, Stainless 20 mm

Maximum load: 300 kg

OREE OR-TG6035 φ15x350mm 1500w Fiber Profile Laser Cutting

Our OR-TG6035 model 1.5kW fiber laser pipe profile cutting machine is designed for precise and fast cutting of materials up to 6,000 mm in length and 350 mm in diameter. It adapts to various types of pipes and profiles with different power options and a wide diameter range.

Working area: 1,530 x 3,050 mm

Laser power: 1,000w – 1,500w

Effective cutting dim of round profile: φ15 – φ350mm

Effective cutting dim of box profile: φ15 – φ350mm

Positioning accuracy: ±0.03 mm

Repeatability accuracy: ±0.02 mm

Max. simultaneous positioning speed: 80 m/min

Acceleration: 0.8 G (max.)

EMMEGI Phantomatic M3 CNC 3+1 Axis Vertical Machining Center

Our CNC work center with automatic rotation of the tool on three fixed positions can process all 3 sides of aluminum, pvc, light alloy bars or parts in general. Positioning is achieved by a pneumatic profile stop on the left and clamping is achieved automatically by 4 clamps via the X axis.

Axis movements X-Y-Z: 3,000 x 274 x 390 mm

Electro chuck auto. positioning: -90° | 0 | +90°

Positioning speed X-Y-Z: 56/22/22/22 m/min

Electro mandrel S1 maximum power: 4 kW

Maximum speed: 20,000 rpm

Tool connection cone: HSK – 50F

Maximum number of manual tool stores: 9 pieces

Automatic tool carrier connection available

Liquid cooling available

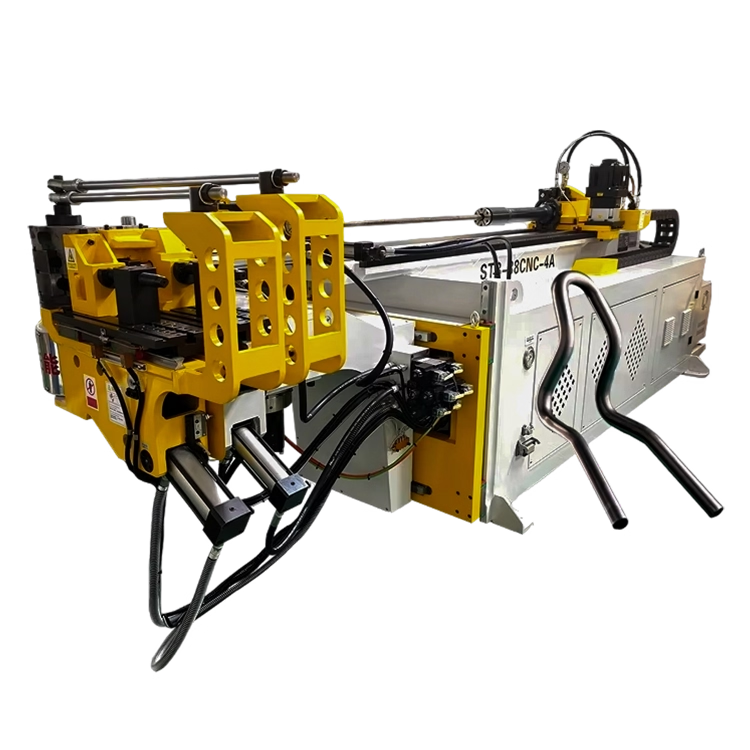

STM STB-38CNC-4A-3S Hybrid Pipe Bending

It offers the possibility to bend pipes with a maximum size of 38 x 2 mm, precisely and up to 190 degrees thanks to servo motors. Thanks to the Rolling feature, we can perform large diameter bends and produce parts with complex geometries with three different radius at the same time.

Max. bending angle: 190°

Bending accuracy: 0.1°

Total motor power: 4kW

Max. tube o.d. bending capacity: 38.1 mm

Max. tube wall thickness: 2 mm

Max. bending stainless steel tube: 32 x 1.8 mm

Max. mandrel working distance: 2,000 mm

Bending, feed, rotation, mold axis: servo

Clamping, trowel, gauge, collet: hydraulic

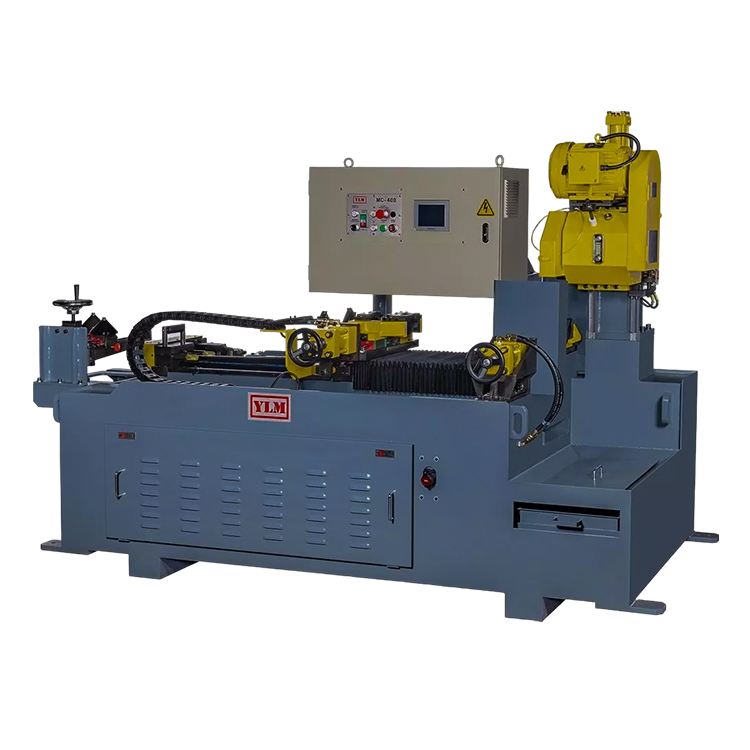

YLM MC-400VO-SA-HT Circular Saw Cutting

With our semi-automatic pipe cutting machine with high efficiency, quick blade change, durable and low spare parts consumption, we are able to cut all kinds of steel pipes and profiles of different shapes, such as mild steel, stainless steel, copper and aluminum for different industries, such as automotive, furniture, connecting tube, etc.

Main shaft motor: 3 HP

Motor speed: Fast 122 rpm / Slow 57 rpm

Saw diameter: ø275 mm – ø400 mm

Hydraulic system: 5HP hydraulic motor

Cooling system: 1/4 HP

Dimensions: 2.688 x 1.188 x 2.053 mm

Pipe diameter: ø110 mm

Square material dimension: 110 mm x 110 mm

Rectangular profile size: 150 mm x 100 mm

Robotmeta 2000/10 HW Industrial Welding Robot

Our fully functional professional welding robot; with its compatible structure with robotic laser tracking sensor, it increases the welding quality and makes production processes more flexible. With innovative welding technologies such as LSA (Low Spatter Arc) and QPT (Short Arc Pulse), it offers cleaner, faster and higher quality results.

Loading capacity: 10 Kg

Reach distance: 2000 mm

Total speed: 2.5 m/s

Repeatability: ±0.05 mm

LSA (Low Spatter Arc for MAG/CO2) technology

QPT (Short Arc Pulse) technology

Ready to work with robotic laser tracking sensor

Welding processes: MIG/MAG/TIG, Spot Welding, Stainless Steel Welding, Aluminum Welding

COASTONE OY CONE 900 Servo-Electric Press Brake

Our 100% electric press brake press brake machine offers high precision and efficiency. The 3-axis CNC control system provides precise movement on the Y1, X and R axes. Our machine works efficiently with high speed approach and return, low speed pressing. Repeatability accuracy: +/- 0.005 mm (X-axis)

Press tonnage: 220 kN

Bend length: 900 mm

Open height: 400 mm (max.)

Open height: 250 mm (min.)

Y-axis stroke: 150 mm

X-axis stroke: 400 mm/s

Y-axis speed: 375 mm/s

Y-axis stroke: 135 mm

Servo power: 5 kW

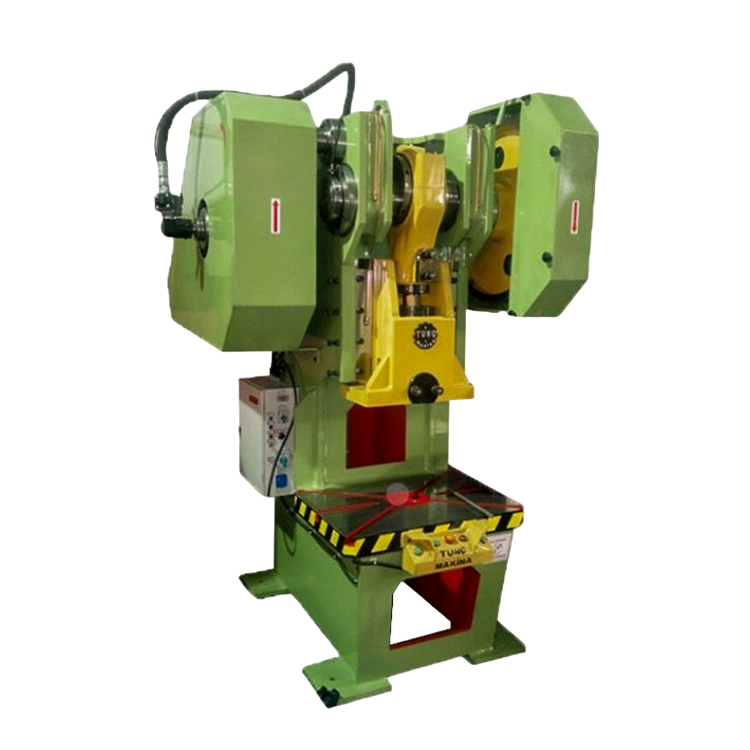

TESBIHCI 30 Ton C Type Eccentric Press

Tesbihci 30 Ton type C eccentric press offers high performance and ease of use with its robust steel construction and automatic lubrication system. It provides a safe working environment thanks to its double coil safety valve. We can make customizations according to the needs of the work to be done with various optional features.

Body: ST 42 steel (reinforced inside and outside)

Type: type C eccentric press

Power: 30-300 Tons (adjustable)

Lubrication: Automatic central lubrication

Control: Piano remote control panel, PLC control

Operation: Semi-automatic – Fully automatic

Gliding: 4-side dovetail system

Grip: Air clutch system

Safety: Double coil valve, hydraulic fuse system

YESILYURT 80 Ton type C Eccentric Press

Yesilyurt 80 Ton type C eccentric press stands out with its robust structure made of high quality materials, adjustable stroke and wide working table. It offers a safe working environment with PLC controlled electrical panel and safety barriers. Adaptable to different production needs thanks to various operating modes and optional features.

Stroke: 0-110 mm (adjustable)

Material: EN-GJS400 quality sfero iron connecting rod

Slide system: Prismatic 4 slides

Number of strokes: 45 strokes/minute

Table dimensions: 800 x 520 mm

Engine power: 7.5 kW

Safety: Mechanical overload fuse, double poppet valve

Operation modes: Mold setting, single press, continuous press

Grip: Air clutch system

VOUGA JB04 – 1 Ton Desktop Eccentric Press

Our VOUGA JB04 bench press can be easily used even in confined spaces thanks to it’s compact design and useful features; this press, which we prefer in many areas such as sheet steel processing, hole punching, is very effective and efficient in pressing, bending and shaping small parts.

Pressure tonnage: 1 Ton

Stroke travel: 40 mm

Distance between table and ram: 150 mm

Table size: 270 x 198 mm

Distance between columns: 106 mm

Table T channel size: 12 mm

Table hole diameter: 28 mm

Coach hole diameter: 20 mm

Engine power: 0.37 kW

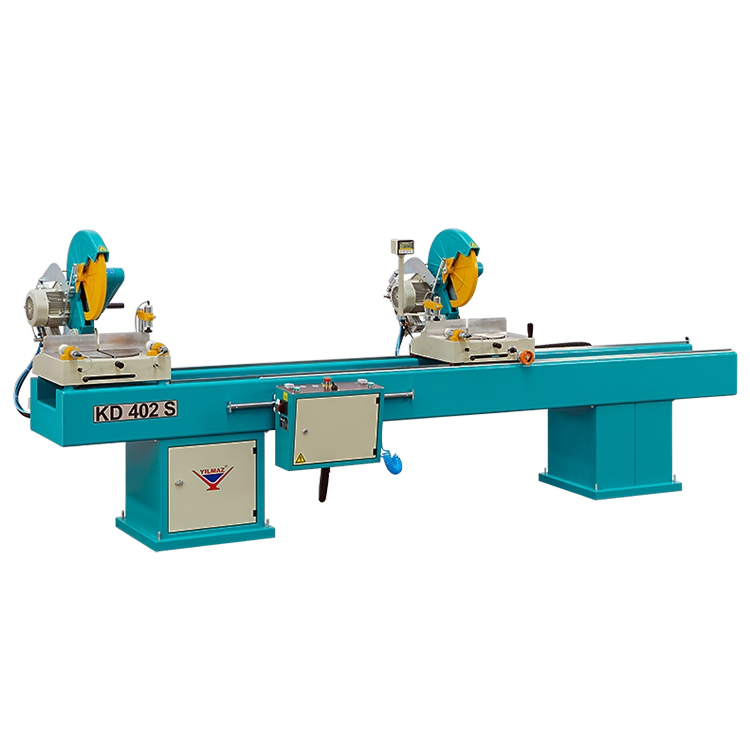

YILMAZ KD 402 S Double Head Straight and Angled Saw Cutting

The KD 402 S is a double-head sawing machine designed for cutting large-sized aluminum and PVC profiles, straight or angled, with high precision. It is especially ideal for cutting long and wide profiles such as window and door profiles.

Saw diameter: Ø 400 mm

Cutting angles: 90°, 45°, 30°, 22.5°, 15° (with inward switchblade)

Cutting length: 530 mm (min.), 3,455 mm (max.)

Number of clamps: 3 horizontal, 2 vertical

Control: Dual hand control

Movement: Hydro-pneumatic

Additional features: Air gun

Cooling system: Spray saw cooling

OZCELIK METEOR I 420 Automatic Undercut Saw

Ozcelik Meteor I 420 is a sawing machine with automatic bottom exit system designed for precise and safe cutting of various profiles such as aluminum, plastic and wood. It is especially preferred in enterprises where windows, doors and similar structures are produced.

Saw diameter: Ø 420 mm

Straight cut: 90°

Angle cut: -45° to +45° (adjustable)

Fixed angles: 0°, 15°, 22.5°, 30°, 45° (right and left)

Engine power: 3 kW

Hydraulic system: Hydraulic unit and valves

Pneumatic system: Vise, saw head movements

Cooling system: Saw coolant system

YILMAZ ACK 420 S Undercut Saw Cutting

Yilmaz ACK 420 S is a professional machine designed for cutting wide profiles such as aluminum and PVC with high precision. It is especially preferred in enterprises where windows, doors and similar structures are produced. It provides high precision cutting thanks to its wide angle range and fine adjustment.

Saw diameter: Ø 420 mm

Fixed angles: 75°, 60°, 45°, 30°, 22.5°, 15°, 0° (right/left)

Intermediate angles: Fine adjustment from -75° to +75°

Cutting capacity: Depends on profile thickness and material.

Speed: Adjustable saw output speed

Control: Dual hand control

Safety: Enclosure with safety sensor

Protection cover: Manual

Additional features: Spray cooling, air gun

ARTIKON SD-201 Automatic Vertical Screwdriver

ARTIKON SD-201 is an automatic machine designed for fast and precise vertical screwing of various materials such as PVC profiles. The screws are fed automatically thanks to air pressure and the screwing process continues without interruption. Screwing is performed safely and at the specified torque value.

Screw feeding system: Pneumatic automatic unit

Screwing type: Automatic with push clutch

Automation: Automatic stop at the end of screwing

Screw height adjustment: Special screw height adjustment switch

Torque setting: Torque adjustment according to the screw used

Screwing speed: Average 1.7 sec/pcs

Screw dimensions: 3.9 x 16 / 4.2 x 38 mm

Workpiece height – width min/max: 40/120 mm

Air pressure: 6 – 8 bars

OZGUR – Pipe Shrinking Machine

Our pipe shrinking machine compresses or expands the pipe with the hydraulic system by using clamp and plastering methods on the pipe ends. In this way, pipe ends up to 150 mm diameter can be given the desired shape and size. We can also make improvements for additional operations such as pipe drilling, grooving, grooving, nail cutting.

Principle of operation: Clamping and rolling

Max. pipe diameter: 150 mm

Engine power: 7.5 kW

Hydraulic pressure: 180 bar

Control system: Foot pedal, push button

Additional features: Pipe drilling, grooving, grooving, nail cutting

Areas of use: Pipes used in automotive, aerospace, construction, energy, food industry

AKYAPAK APK 30 Akbend Ring Profile Bending

This compact and handy machine allows us to bend small diameter profiles with high precision. It can easily process profiles of different cross-sections in various materials such as steel and aluminum. Generally for the automotive sector, we perform the type of bending that is characterized as endless bending.

Material bending dimensions:

– I-steel 50 x 10 mm (max.)

– angle steel 50 mm (max.)

– round material 30 mm (max.)

Maximum bending diameter: 1 1/2″ (approx. 38 mm)

Motor power: 0.75 kW

Weight: 0.185 tons

Dimensions: 670 x 530 x 1,350 mm

Horizontal and vertical bending

AKYAPAK APK 45 Akbend Hydraulic Profile Bending

We prefer Akyapak APK 45 for our larger and more challenging bending jobs. Thanks to its powerful motor and durable structure, it can easily bend even thick profiles at different angles. We can also serve different sectors with its ability to process profiles in various metal types. It can be customized for profiles.

Material bending dimensions:

– I-steel 80 x 15 mm (max.)

– angle steel 45×5 mm (max.)

– round material 35 mm (max.)

– pipe diameter 60 x 2 mm

Maximum bending diameter: 1 1/2″ (approx. 38 mm)

Engine power: 2.25 kW

Weight: 0.5 tons

Dimensions: 780 x 950 x 1,450 mm

BOSCH PBD 40 Bench Drill

The Bosch PBD 40 bench drill allows us to drill easily and accurately in a variety of materials. We can easily monitor the drilling speed and depth on the digital display, and thanks to the stepless speed adjustment, we can set the optimal speed for the job. The chuck holds even round materials firmly, ensuring precise drilling.

Input power: 710 W

Idle speed: 200 – 850 / 600 – 2,500 rpm

Laser type: 650 nm

Laser class: Class 2

Max. drilling diameter in steel: 13 mm

Max. drilling diameter in wood: 40 mm

Clamping range of the chuck: 1.5 – 13 mm

Drilling stroke: 90 mm

Dimension (base plate): 330 x 350 x 30 mm

TAMIS TZ11/2K Double Arm Belt Sander

Tamiş TZ11/2K is a double arm industrial belt sander for metal and wood surfaces. Thanks to its robust construction and powerful motor, it is suitable for intensive use and allows fast and effective sanding of large surfaces.

Usage: Sanding metal and wood surfaces

Double armed: Yes

Belt sander size: 1.150 / 1.250 x 100 mm

Engine power: 2/3 HP

Engine rpm: 3,000 rpm

Voltage: 380 V

Weight: 55 kg

Dimensions: 750 x 1,000 x 900 mm

MAGMAWELD Argon TIG Welding

Our Magmaweld brand TIG welding machines offer high efficiency thanks to their inverter technology and enable us to achieve successful results in different welding processes. Pulse feature provides high quality in welding thin metals. Saves time by memorizing different welding parameters.

Source current adjustment range: 5 – 300 ADC

Rated welding current: 300 A (%30)

Electrode diameter: 1.60 – 5.00 mm

Tungsten electrode diameter: 1.00 – 2.40 mm

Cooling mode: Air

TIG arc ignition: HF or Lift TIG

Pulse frequency setting: Yes

Program memories: 10 pieces

OERLIKON GKG 350 MIG/MAG Gas Metal Arc Welding Machine

Thanks to its inverter technology, the Oerlikon GKG 350 enables excellent welding results in different materials with high productivity. It can be used on different materials such as steel, stainless steel and aluminum. The welding voltage and wire feed speed (welding current) are precisely adjusted on the front panel.

Welding current adjustment range: 50 – 350 A

Rated welding current: 350 A (%40)

Open circuit voltage: 62 V

Wire driving speed: 1-24 m/min

Torch trigger control: 2/4

Welding wire diameter: 0.60 – 1.20 mm

Protection class: IP23

Spool capacity: Ø300, Ø270, Ø200 mm

CO2 heater: 24V

“At the Heart of the Industry, We Produce with Quality”

Built on the strong foundations of Can Otomotiv, Can Metals is the right address where you can find solutions for all your needs such as design, product development, machining, mold design and production, pipe and sheet metal laser cutting, injection printing, welded production. Thanks to its advanced machine park and expert staff, it manufactures its own developed products and delivers them to end users in the global arena and is an innovative company specialized in contract manufacturing.