About Pet Blow molding injection molds

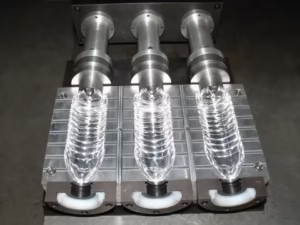

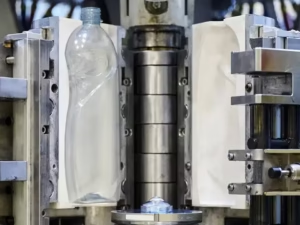

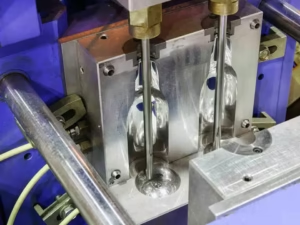

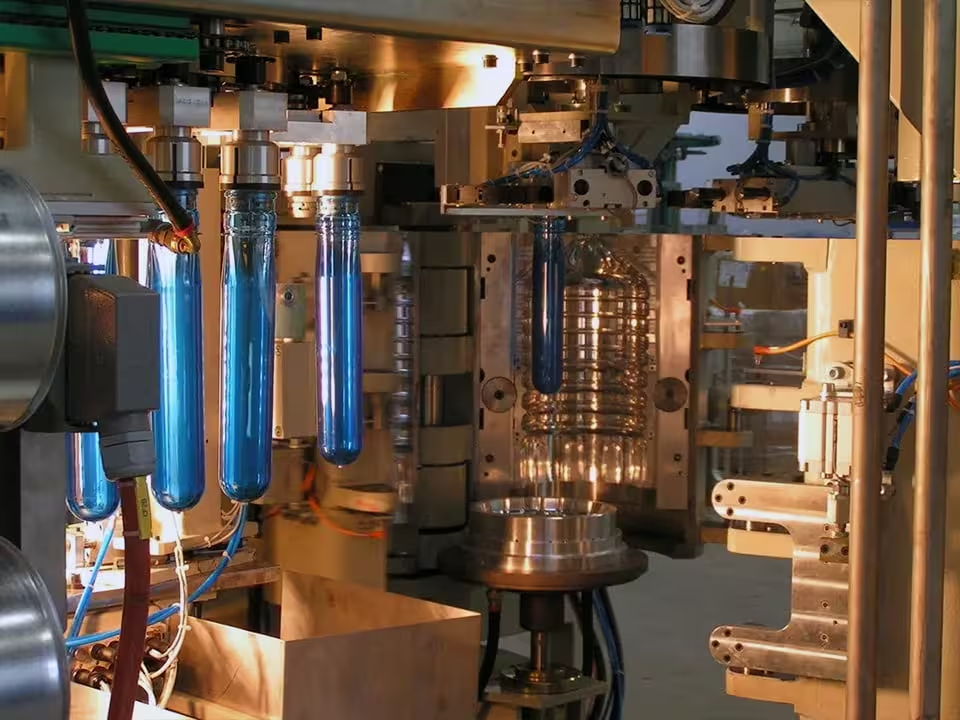

The production of blow injection molds is a process that requires high precision. Mold materials, usually steel or aluminum alloys, have a direct impact on the durability and lifetime of the product. The inner surface of the mold is the mirror of the outer surface of the product and determines the quality of the product. Therefore, tolerances are very tightly controlled during mold production. Blow injection molds are widely used in many industries such as automotive, cosmetics, food and pharmaceuticals.

“At the Heart of the Industry, We Produce with Quality”

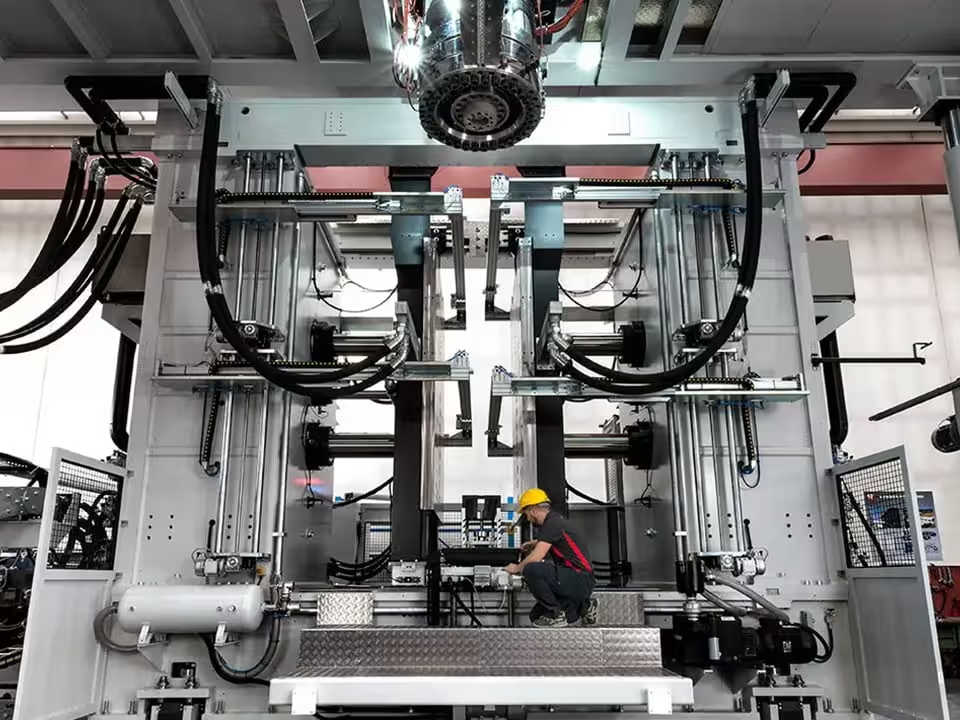

Built on the strong foundations of Can Otomotiv, Can Metals is the right address where you can find solutions for all your needs such as design, product development, machining, mold design and production, pipe and sheet metal laser cutting, injection printing, welded production. Thanks to its advanced machine park and expert staff, it manufactures its own developed products and delivers them to end users in the global arena and is an innovative company specialized in contract manufacturing.

With our expertise in blow molding technology, we design and manufacture high-volume production-ready molds for hollow plastic products.