Production excellence with thermoforming molds

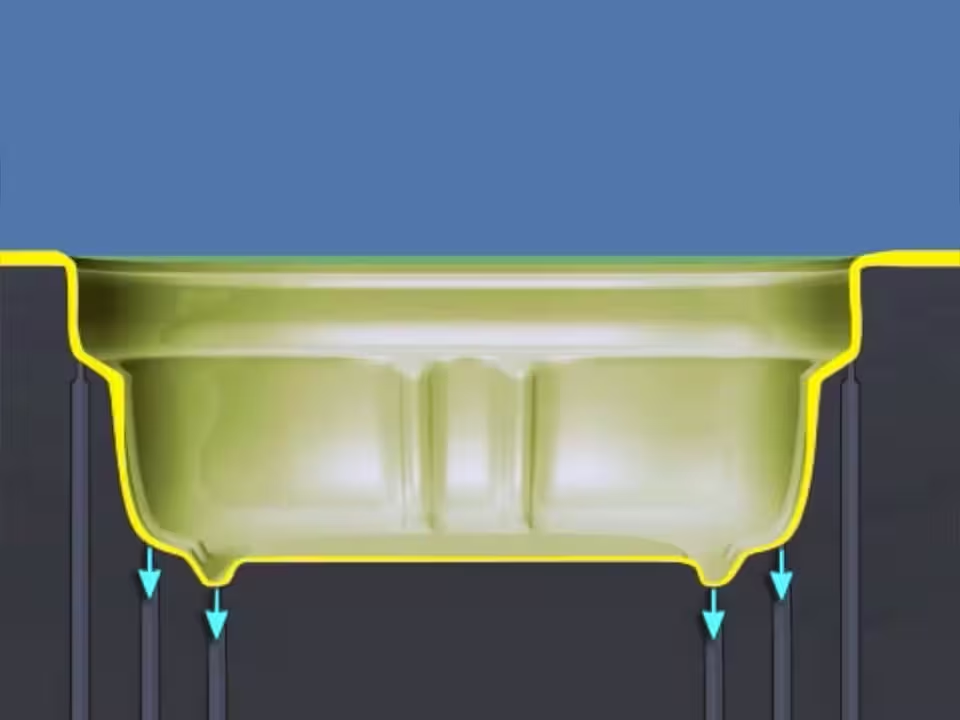

Thermoform vacuum, also known as vacuum forming or thermo-vacuum forming, is the process of forming plastic sheets that are softened by heating and pulled onto a mold with the help of a vacuum. This method allows plastic sheets of different thicknesses and types to be transformed into three-dimensional products with complex geometries.

“At the Heart of the Industry, We Produce with Quality”

Built on the strong foundations of Can Otomotiv, Can Metals is the right address where you can find solutions for all your needs such as design, product development, machining, mold design and production, pipe and sheet metal laser cutting, injection printing, welded production. Thanks to its advanced machine park and expert staff, it manufactures its own developed products and delivers them to end users in the global arena and is an innovative company specialized in contract manufacturing.

With vacuum forming expertise, we help you produce perfect products with high-precision thermoforming molds.