Advantages of Can Metals:

Our Services

As Can Metals, thanks to our expert team and advanced technology, we offer our customers customized solutions and comprehensive services that can meet their needs in the sector. By prioritizing customer satisfaction, we complete projects on time and on budget.

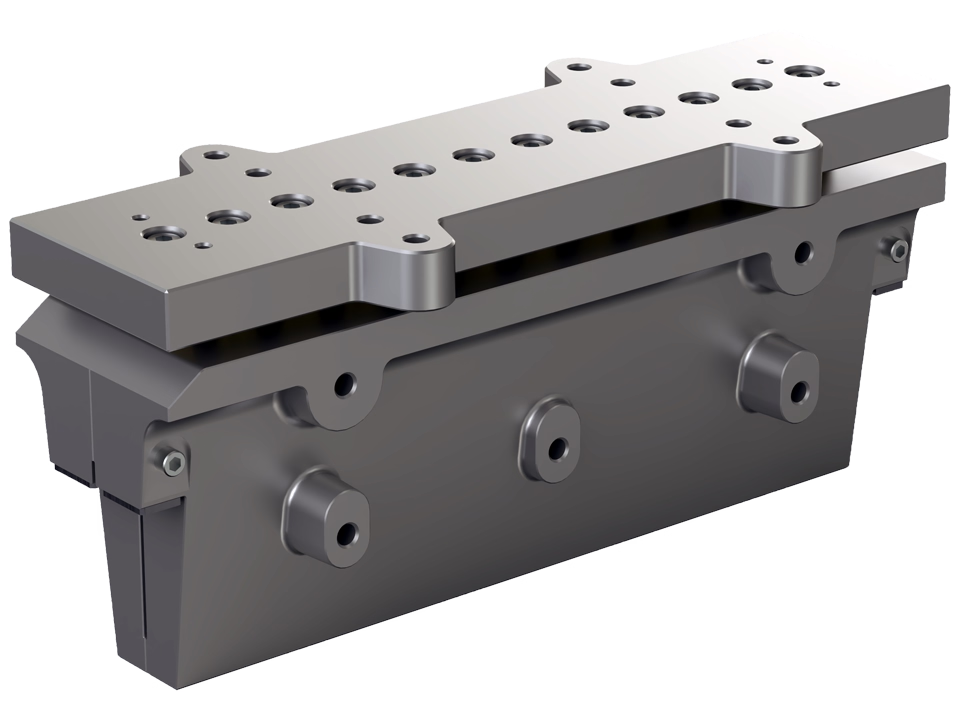

Mold Design & Mold Manufacturing

We design and manufacture the molds that bring your products to life using the latest technology and our expert team. Precision and high quality are always our priorities.

Cone Mold

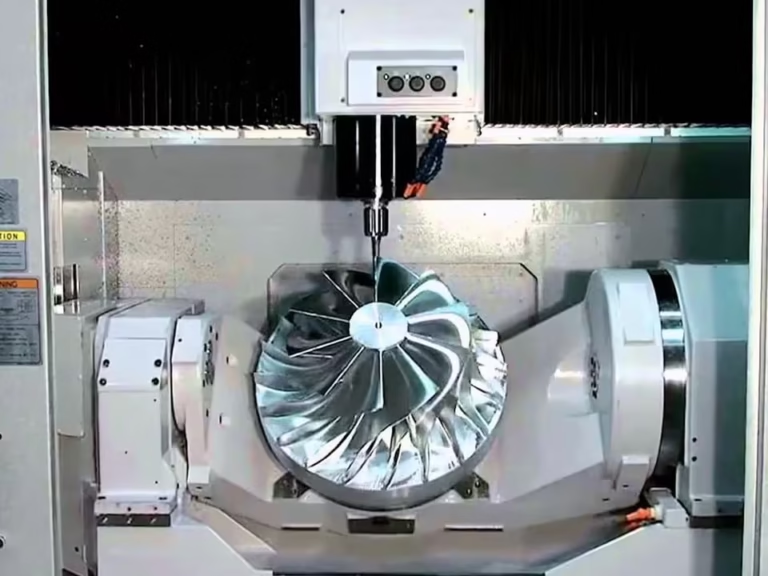

As Can Metals, we carefully evaluate the needs and design requests for ice cream cones and waffle products, designing, developing, and manufacturing the most suitable custom molds in our 5-axis precision CNC machining centers.

Wafer Cone Mold

With our extensive experience in metal processing, expertise in 3D design and product development, and a powerful machine park equipped with a 5-axis CNC machining center, we produce high-quality precision cone and wafer molds.

We create highly precise 3D prototypes with our original designs for new cone models and manufacture molds that fit your machine 100% after sample approval.

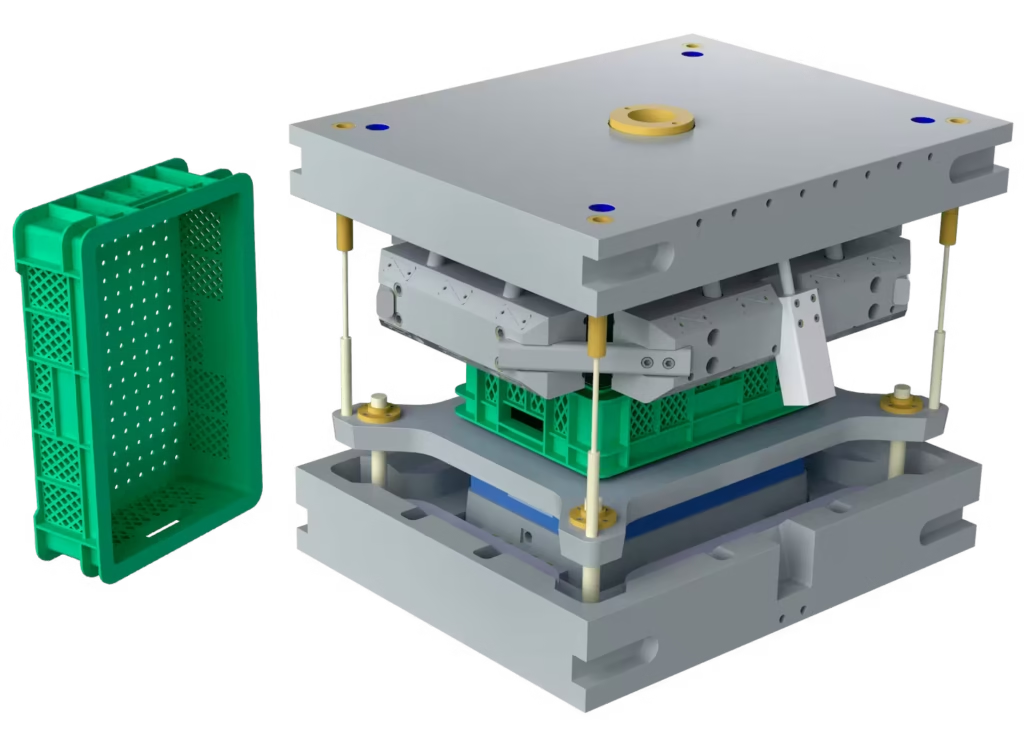

Plastic Crate Mold

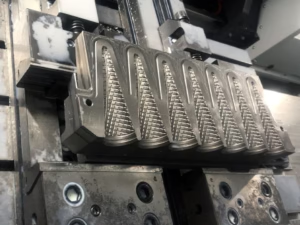

In plastic crate injection mold production, we analyze the 3D model of your product down to the finest details, create our designs, and manufacture with high precision in our CNC machining centers.

Mold steel selection and hardening processes extend the mold’s lifespan, providing you with a long-term investment. Finally, we perform all pre-production checks by testing the mold in the injection machine.

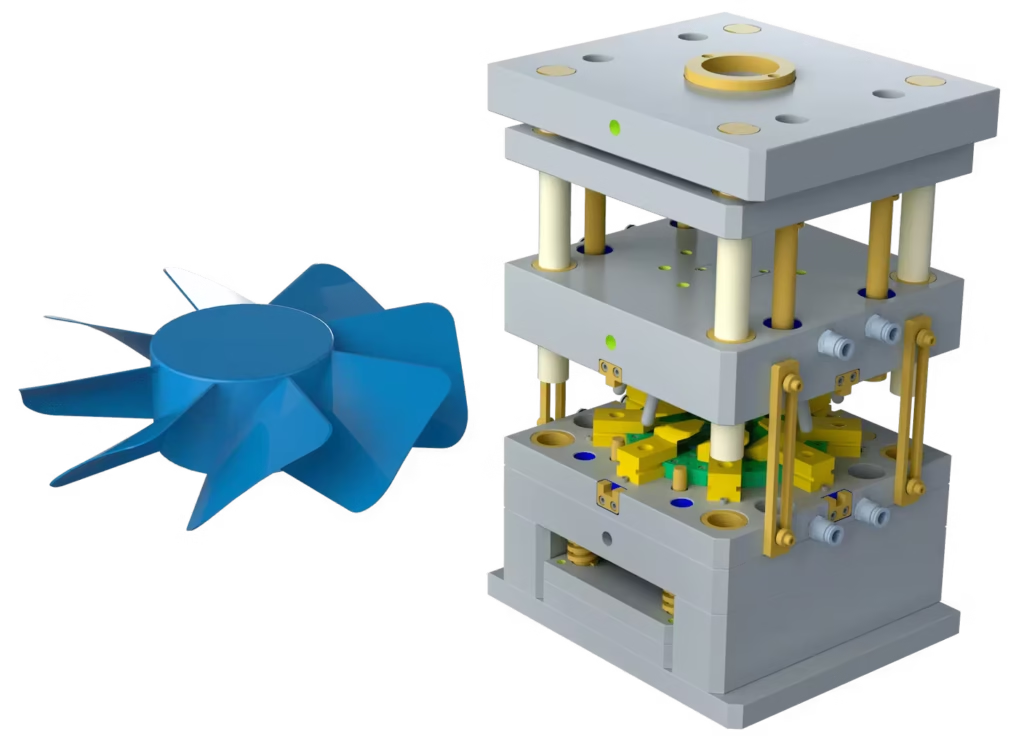

CPU Fan Mold

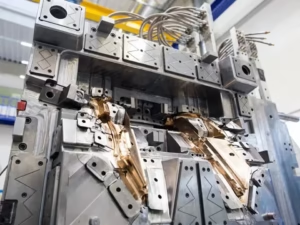

Using 3D scanning and reverse engineering methods, we design models in CAD programs. We determine parting surfaces suitable for the part’s geometry and the mold’s working principle, designing the mold steels and movable cores accordingly.

In the CPU fan mold, there are as many movable cores as the number of fan blades. We optimize the production process through simulations using state-of-the-art CAD/CAM software.

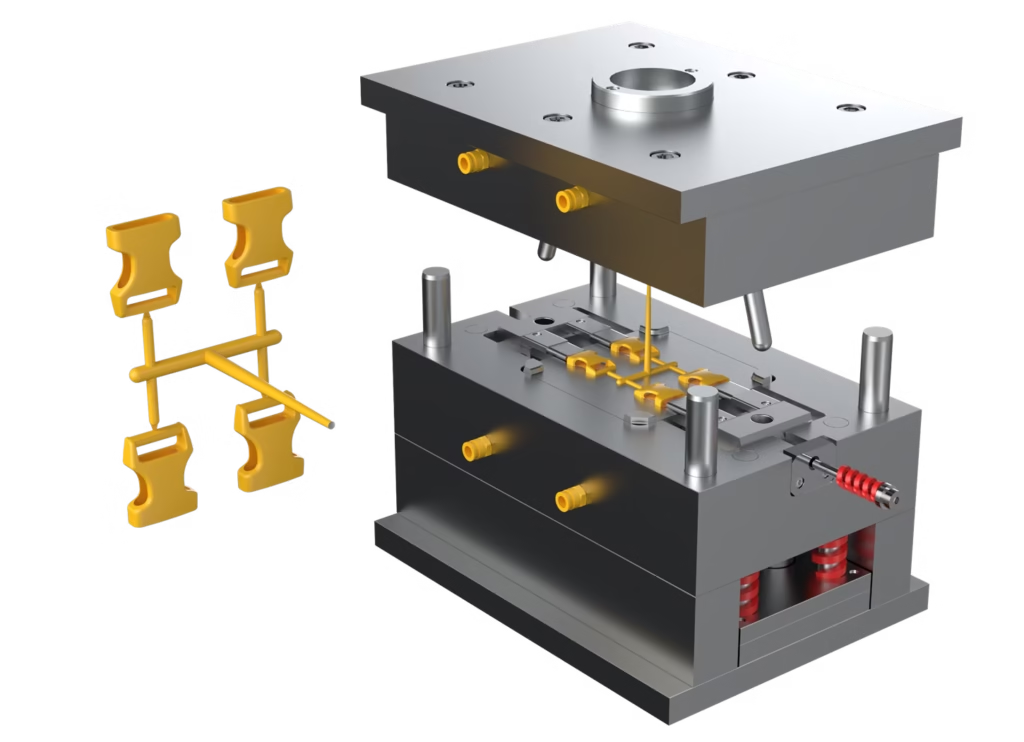

Plastic Buckle Mold

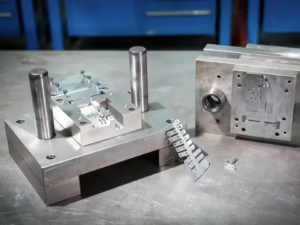

Plastic buckle mold manufacturing is the design and production process of special molds used in the production of plastic buckles that we frequently encounter in daily life. These molds enable the molten plastic material to be shaped into a certain shape, making it possible to obtain buckles with the desired design.

The materials used are special steel alloys resistant to high temperatures and wear. The modeling process of the buckle must be done with precise measurements and tolerances.

Stages of Product Development with 3D Design

Quality Control and Laboratory

Plastic Injection Molding and Production

Laser Cutting Bending Metalworking

CNC Machining and EDM Plunge Erosion

CNC Bending and Welding Fabrication

Assembly, Packing and Packaging

Aluminum Vertical Machining 3+1 Axis

“At the Heart of the Industry, We Produce with Quality”

Built on the strong foundations of Can Otomotiv, Can Metals is the right address where you can find solutions for all your needs such as design, product development, machining, mold design and production, pipe and sheet metal laser cutting, injection printing, welded production. Thanks to its advanced machine park and expert staff, it manufactures its own developed products and delivers them to end users in the global arena and is an innovative company specialized in contract manufacturing.