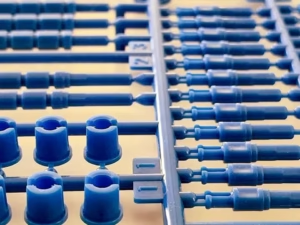

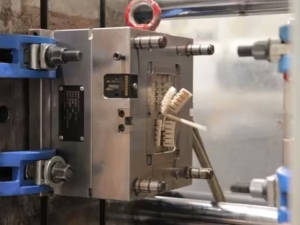

Precision and Efficiency in Plastic Injection Molding

Benefits and Consequences

The advantages of plastic injection molding and the results you will achieve:

Versatile Material Handling Capability

With injection molding, we can mold almost any kind of plastic and produce products with different properties.

Voices of Those Who Trust Us

“At the Heart of the Industry, We Produce with Quality”

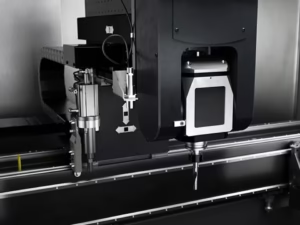

Built on the strong foundations of Can Otomotiv, Can Metals is the right address where you can find solutions for all your needs such as design, product development, machining, mold design and production, pipe and sheet metal laser cutting, injection printing, welded production. Thanks to its advanced machine park and expert staff, it manufactures its own developed products and delivers them to end users in the global arena and is an innovative company specialized in contract manufacturing.