EXPORTS MORE THAN 40 COUNTRIES

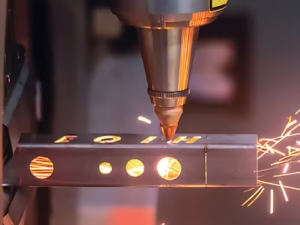

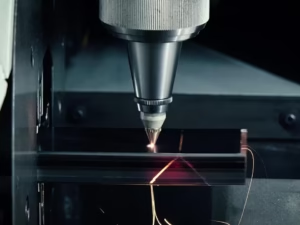

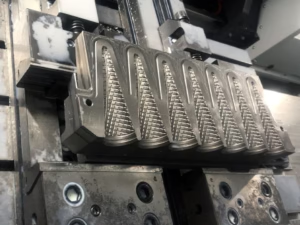

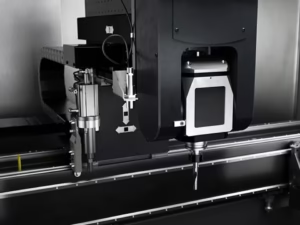

As Can Metals, with more than 40 years of experience, we export our high quality products and metalworking solutions to more than 40 countries around the world. By always prioritizing customer satisfaction and quality, we are recognized as a reliable business partner in the international market. With our advanced technology, expert staff and sustainable production approach, we continue to add value to the metalworking industry on a global scale.

Algeria

Algeria

Australia

Australia

Austria

Austria

Azerbaijan

Azerbaijan

Belarus

Belarus

Bulgaria

Bulgaria

Canada

Canada

Czech Republic

Czech Republic

Denmark

Denmark

Egypt

Egypt

France

France

Georgia

Georgia

Germany

Germany

Greece

Greece

Hungary

Hungary

Iceland

Iceland

Ireland

Ireland

Israel

Israel

Italy

Italy

Jordan

Jordan

Kazakhstan

Kazakhstan

Latvia

Latvia

Libya

Libya

Lithuania

Lithuania

Malta

Malta

Moldova

Moldova

Morocco

Morocco

Netherlands

Netherlands

Norway

Norway

Panama

Panama

Poland

Poland

Romania

Romania

Serbia

Serbia

Slovakia

Slovakia

Spain

Spain

Sweden

Sweden

Taiwan

Taiwan

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

Ukraine

Ukraine

United Arab Emirates

United Arab Emirates

United Kingdom

United Kingdom

United States

United States

Uzbekistan

Uzbekistan

Voices of Those Who Trust Us

I bought crossbars for my RAV4. They have a very sturdy and stylish design. The post-sales support is excellent. I highly recommend it.

I believe the company truly deserves five stars for the support, information, and attention provided by the factory.

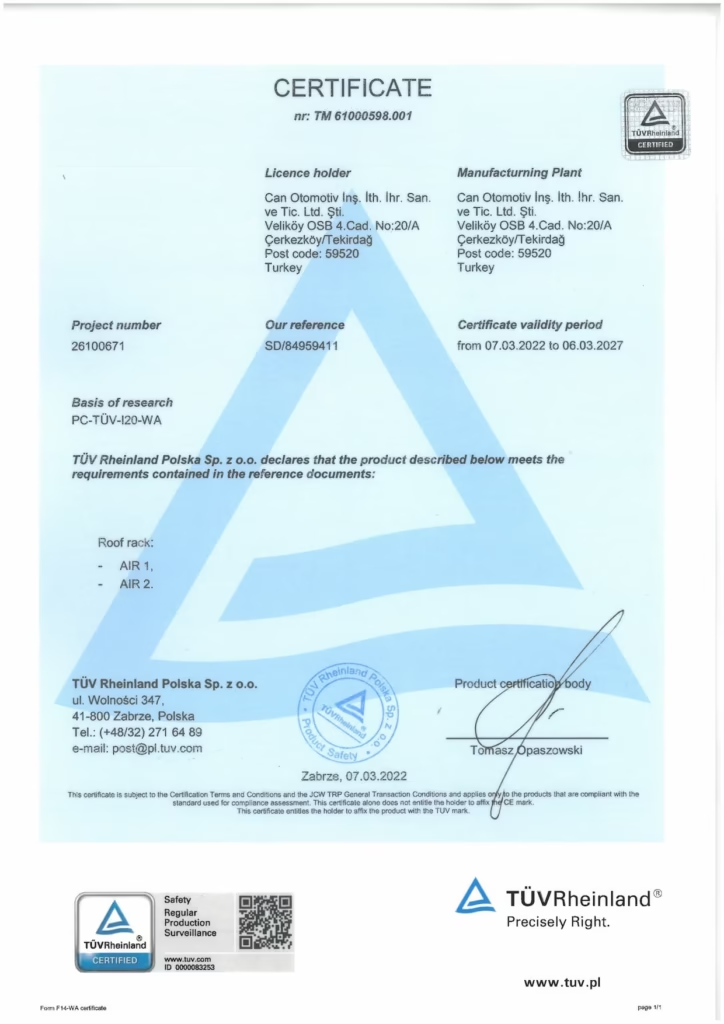

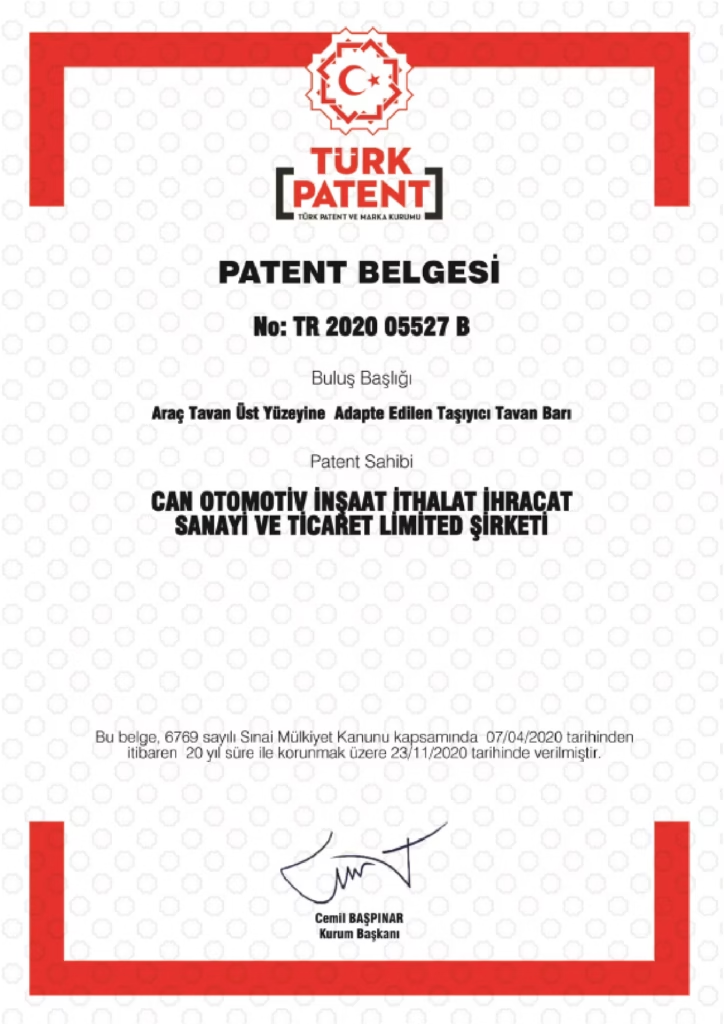

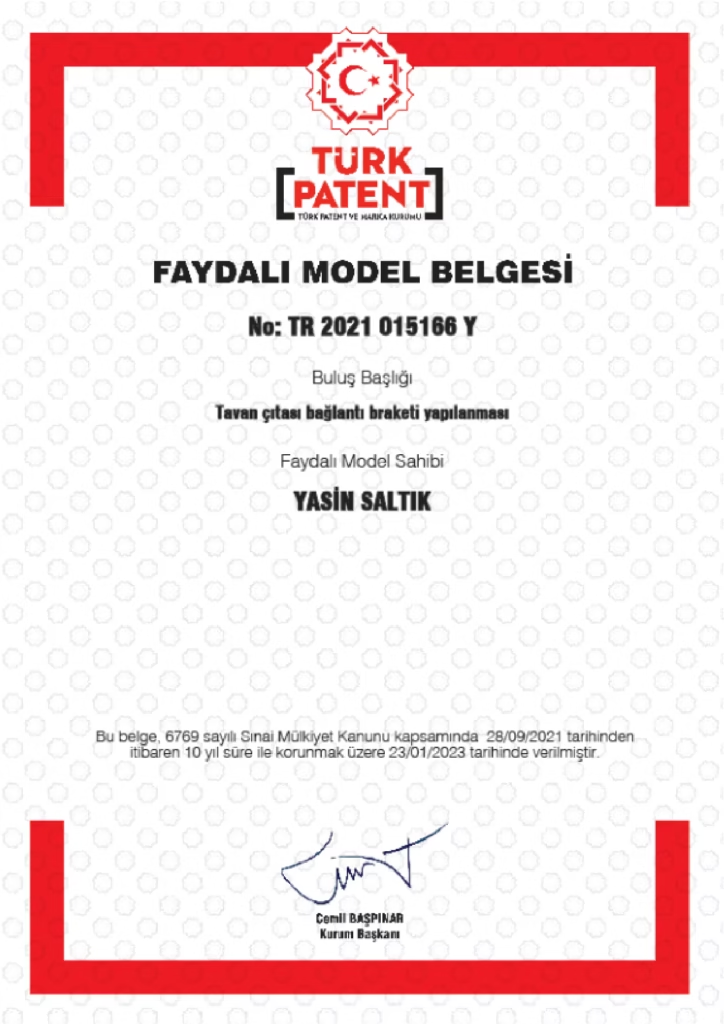

We Follow Best Practices

“Customer satisfaction is our top priority. Therefore, we follow and implement the best practices in the industry to meet our customers’ expectations in the best possible way.”