Fiber Laser Cutting Technology: Precision and Efficiency

Benefits and Consequences

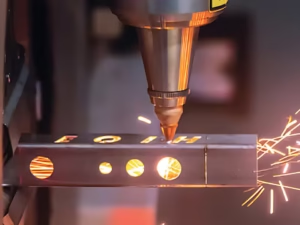

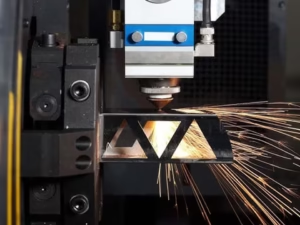

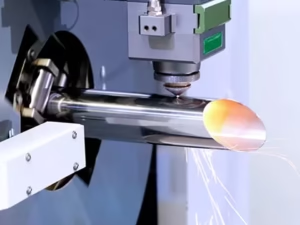

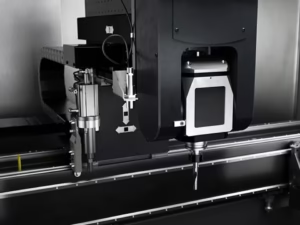

Fiber laser technology provides much more precise and efficient results than traditional cutting methods. Thanks to our 6kW fiber laser systems:

Versatile Material Processing Capability

With our laser cutting systems, we achieve perfect results in various metals:

Nesting at Maximum Efficiency

Thanks to the advanced nesting software we use in our production processes:

Application Areas

Our laser cutting and bending technologies serve many sectors:

Benefits and Consequences

From prototype to mass production, we have a wide range of solutions. Ideal for parts that require high precision, these methods improve the quality and extend the life of your products.

They are also often preferred for the production of molds with complex geometries. This way, you can speed up your new product development processes and reduce your production costs.

Voices of Those Who Trust Us

“At the Heart of the Industry, We Produce with Quality”

Built on the strong foundations of Can Otomotiv, Can Metals is the right address where you can find solutions for all your needs such as design, product development, machining, mold design and production, pipe and sheet metal laser cutting, injection printing, welded production. Thanks to its advanced machine park and expert staff, it manufactures its own developed products and delivers them to end users in the global arena and is an innovative company specialized in contract manufacturing.